Introduction

In today's modern world, remote operations have become a common practice across various industries such as telecommunications, mining, construction, and agriculture. The ability to control and monitor operations from a remote location offers numerous benefits including increased efficiency, cost savings, and improved safety. However, one of the key challenges faced by remote operations is ensuring a reliable and continuous power supply to support critical equipment and infrastructure. This is where diesel generators play a crucial role in providing a dependable source of power in remote locations where access to the electrical grid is limited or nonexistent.

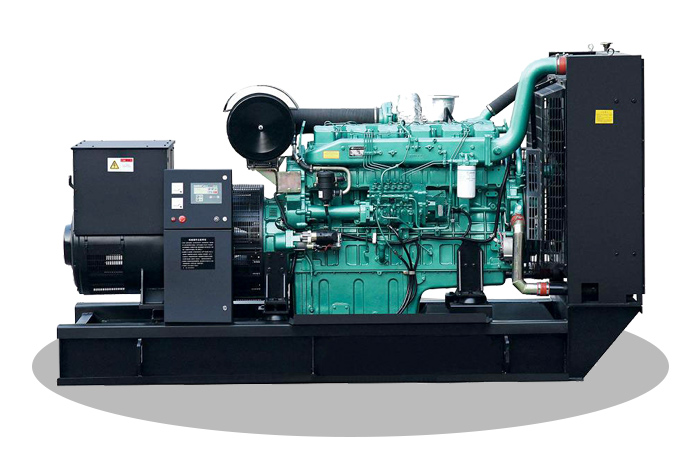

Diesel generators have long been recognized for their ability to provide reliable and efficient power generation, making them an ideal choice for remote control applications. In this comprehensive guide, we will explore the various aspects of diesel generators for remote operations, including their benefits, key features, maintenance requirements, and best practices for ensuring optimal performance.

Benefits of Diesel Generators for Remote Control

1. Reliability: One of the primary benefits of diesel generators is their high reliability. Diesel engines are known for their durability and robustness, making them well-suited for operating in harsh and remote environments. Diesel generators can withstand extreme temperatures, high altitudes, and challenging weather conditions, ensuring continuous power supply when it is needed the most.

2. Fuel Efficiency: Diesel generators are highly fuel-efficient compared to other types of generators, making them a cost-effective choice for remote operations where fuel availability may be limited. Diesel engines are known for their high energy density, which means they can produce more power with less fuel consumption, resulting in lower operational costs in the long run.

3. Easy Maintenance: Diesel generators are relatively easy to maintain, requiring less frequent servicing compared to other types of generators. Diesel engines are designed for heavy-duty use and are less prone to wear and tear, reducing the need for frequent repairs and downtime. Routine maintenance tasks such as oil changes, filter replacements, and fuel system checks can be easily performed by trained personnel, ensuring the longevity and reliability of the generator.

4. Remote Monitoring and Control: Diesel generators can be equipped with advanced monitoring and control systems that allow operators to remotely monitor the generator's performance, fuel levels, and maintenance schedules. This enables proactive maintenance planning, early detection of potential issues, and quick response to emergencies, ensuring uninterrupted power supply to critical equipment and infrastructure.

Key Features of Diesel Generators for Remote Control

1. Power Output: Diesel generators are available in a wide range of power outputs to meet the specific requirements of remote control applications. Whether powering a small communication tower or a large mining operation, diesel generators can be sized accordingly to provide the necessary power capacity to support the load.

2. Portability: Portable diesel generators are ideal for remote operations where mobility is required. These generators are compact, lightweight, and easy to transport, making them suitable for temporary or mobile applications such as construction sites, disaster relief operations, and outdoor events.

3. Soundproofing: Noise pollution can be a concern in remote locations, especially in residential areas or sensitive environments. Diesel generators can be equipped with soundproof enclosures or mufflers to reduce noise levels and minimize disturbances to nearby residents or wildlife.

4. Fuel Storage: Diesel generators require a constant supply of fuel to operate efficiently. In remote locations where access to fuel stations may be limited, adequate fuel storage facilities should be in place to ensure uninterrupted operation of the generator. Proper fuel storage practices, such as using clean and stable fuel, monitoring fuel levels regularly, and implementing fuel rotation strategies, are essential to prevent fuel contamination and degradation.

Maintenance Requirements for Diesel Generators

Proper maintenance is essential to ensure the reliable and efficient operation of diesel generators in remote control applications. Regular maintenance tasks should be performed according to the manufacturer's guidelines and best practices to prevent breakdowns, prolong the generator's lifespan, and minimize downtime. Some key maintenance requirements for diesel generators include:

1. Regular Inspections: Visual inspections of the generator should be conducted regularly to check for signs of wear, leaks, or damage. Components such as belts, hoses, filters, and connections should be inspected for proper functioning and replaced if necessary.

2. diesel generator efficiency and Filter Changes: Regular oil changes are essential to keep the engine running smoothly and prevent premature wear. Oil filters should also be replaced at recommended intervals to ensure optimal filtration and lubrication of the engine components.

3. Fuel System Maintenance: The fuel system of the diesel generator should be inspected and cleaned periodically to remove any contaminants or impurities that may affect the engine's performance. Fuel filters should be replaced regularly to prevent clogging and ensure clean fuel delivery to the engine.

4. Battery Maintenance: The battery of the diesel generator should be inspected for corrosion, electrolyte levels, and proper connections. Batteries should be charged regularly to maintain optimal performance and prevent starting issues.

Best Practices for Optimal Performance

To ensure the optimal performance of diesel generators for remote control applications, operators should follow these best practices:

1. Regular Monitoring: Implement a comprehensive monitoring system to track the generator's performance, fuel consumption, and maintenance schedules. Remote monitoring tools can provide real-time data on the generator's status, enabling operators to detect issues early and take corrective actions promptly.

2. Fuel Quality Control: Use high-quality, clean diesel fuel to prevent contamination and ensure efficient combustion. Regularly test the fuel for water content, sediment, and microbial growth, and implement fuel treatment measures as needed to maintain fuel quality.

3. Load Management: Proper load management is essential to prevent overloading the generator and ensure optimal efficiency. Avoid running the generator at full load continuously, as this can lead to overheating, increased fuel consumption, and premature wear of engine components.

4. Emergency Preparedness: Develop a comprehensive emergency response plan to address potential issues such as power outages, equipment failures, or fuel shortages. Maintain a stock of spare parts, tools, and emergency supplies to quickly address any unforeseen circumstances and minimize downtime.

Conclusion

Diesel generators play a vital role in powering remote control operations across various industries, providing a reliable and efficient source of power where grid connection is limited or unavailable. With their high reliability, fuel efficiency, and ease of maintenance, diesel generators are well-suited for remote applications that require continuous and uninterrupted power supply. By following best practices for maintenance, monitoring, and fuel management, operators can ensure the optimal performance of diesel generators and support the successful operation of remote control systems. In an increasingly connected world, diesel generators will continue to be a critical component of remote operations, enabling businesses to operate efficiently and effectively in remote and challenging environments.